This is an elementary guide for 3D printer owners to choose a board properly to your need. We sorted some fundamental information in this first part to help you have a good basic understanding of it and make your wise purchase decision.

What is a mainboard to a 3D printer?

The main board is like the brain of the whole machine. The CPU/MCU is the core of the brain, it interprets the data (gcode) into a language that each part of the mainboard can understand so as to command the connected parts of the 3D printer to execute the operations. Therefore, a mainboard to a 3D printer is quite significant. An experienced 3D printer owner will search for a non-original mainboard on the market, so is there any knowledge about choosing a mainboard that you need to know?

What are the common needs of a mainboard?

You may have different needs for a mainboard. Common needs may include: 1) Looking for a replacement/little upgraded board for the using printer, 2) Need a specific new feature or want to DIY the features of the mainboard, 3) Assemble your own printer and need a mainboard kit, 4) Upgrade the printer to run Klipper firmware.

What do you need to look into?

Let me take an example of that if you are looking to find a mainboard to replace your broken one and would also like to experience some new features, then you may need to consider the following aspects:

1) Enough stepper motor & driver ports

The most fundamental feature of a qualified 3D printer board is to get the stepper motors to execute the movement of the X/Y/Z axis and the extrusion mechanism. In order to achieve that command and execution, a mainboard must have the stepper motor driver (ports) and sufficient stepper motor ports.

①Stepper motor

We all know that the common I3 structure printers generally have 4~7 motors, including 1~2 X-axis motor, 1 Y-axis motor, 1~2 Z-axis motors, and 1~2 extruder motors.

The most classic I3 structure printer Ender-3 has only 4 motors: 1 X-axis motor, 1 Y-axis motor, 1 Z-axis motor, and 1 extruder motor. Other printers may add additional motors for extra features. Example 1: Ender-3 S1 is featured with Dual-Z axis, both screw rods of the Z-axis are equipped with one stepper motor respectively to realize consistent movement of both sides to enhance stability and precision. Therefore, Ender-3 S1 has 5 motors. Example 2: Sovol SV04 is featured with not only Dual-Z axis but also Dual-nozzle printing, so it has two Z-axis motors plus two extruder motors and two X-axis motors. The total number of motors of SV04 come to 7.

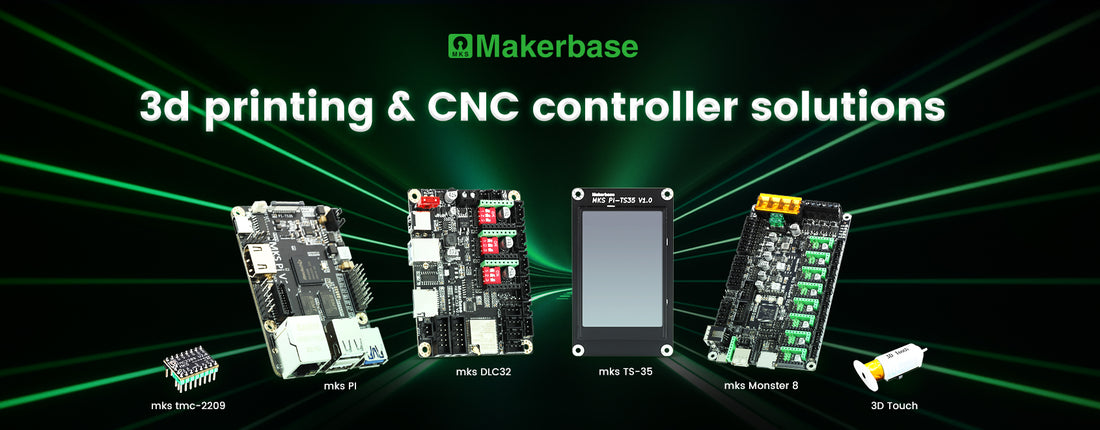

Therefore, if you need to replace the mainboard for Ender-3, you need a mainboard with at least 4 motor ports such as MKS Robin E3 (5 motor ports). But when you replace the mainboard for SV04, you need a mainboard with at least 7 motor ports such as MKS Monster 8 V2 (9 motor ports).

② Stepper motor driver

It is a module that converts the gcode calculated by the MCU into electrical signals that can be read by stepper drivers, so you need to make sure that there are enough drivers to instruct the printer's motors. Here is the question: How do you the number of drivers you need on the mainboard?

Generally speaking, the motor corresponds to the motor driver one by one. If your printer has 4 motors, it needs 4 motor drivers accordingly. However, if your printer has dual Z-axis (5 motors in total), how many motors do you need? The answer is 4~5.

In order to understand why the dual Z-axis printers only need 4 motor drivers, we first need to know the dual Z-axis is to make the left and right axes to do the same movement(left rod and right rod are equipped with a motor respectively). The instructions for the 2 Z-axis motors are consistent, so the required computing work can be reduced to be handled by a single motor driver. Makerbase, therefore, makes 2 Z-axis motors connect with 1 motor driver, allowing 1 driver to control 2 motors. That is why we often find that MKS mainboards have more motor ports than motor driver ports.

By the way, not all mainboards come with motor drivers! Most MKS mainboards don't have embedded drivers, only the ports. This is to allow you to choose drivers according to your own needs: A. If you don't care about the noise from the motors caused by non-silent motor drivers, you can go to the cheap A4988 driver; B. If you would put the printer in a working or living room and you can't bear the noise, you will need these common silent motor drivers: TMC2225 ≈ TMC2208 < TMC2226 ≈ TMC2209; C. If you need to drive a high-power motor, you will use an external motor driver, such as TMC2160-57; D. If you need to achieve highly precise motor control, a closed-loop motor that places the motor driver directly on the motor can meet your needs, such as MKS SERVO 42C.

*If you don't know the exact difference between a silent driver and a non-silent driver, here is a video comparing the noise level under control of A4988 and TMC2208: https://www.youtube.com/watch?v=Lx40lJkk9NQ

2) Supprted firmware

Most of the makers replace their mainboards in order to run a newer version of firmware (and of course, the new features that come with it), so whether your mainboard can run the firmware desired is essential.

① Hardware requirement

You may encounter various unordinary problems when using your 3D printer. For example, when you do manual leveling, the nozzle does not stop but moves to the next position without pausing for a while. You don’t even have enough time to level the bed; or there is a misspelled word on the screen option that you can't stand with, etc. These may be just the bugs of the firmware. By updating the firmware, these abnormal troubles can easily be solved. Not only the brands are constantly fixing bugs of the firmware and providing updatable firmware versions, but many experienced engineers contributes their own firmware versions for specific 3D printers. They may update it more often than the brands and moreover, develop features to make the printer capable of more functions. However, sometimes you will find you cannot go straight and upgrade to that firmware because your existing mainboard is not eligible.

For instance, Creality Ender-3 and 3 Pro, in early production, were both equipped with 8-bit mainboards, but then Creality changed to equip 32-bit mainboards as a standard. When the users who bought the printers early want to update the firmware, they may find that as 32-bit mainboards are increasingly popular, many firmware versions will require a 32-bit board, so they need to consider to replace the board.

② 32-bit boards difference

We all know that a 32-bit mainboard can process data way faster than the classic 8-bit, but do you know there still can be a difference between 32-bit boards? For example, the processing frequency of the Creality V4.2.2 and V4.2.7 is 72MHz, while the MKS Robin Nano V3.1 is 168MHz, which is developed by Makerbase specifically for Creality Ender 3, 3Pro, 3V2 3D printers and its processing frequency can be 2 times more than the original boards. With the firmware versions being constantly updated, the data that needs to be processed and calculated will become larger, so a higher processing efficiency is more beneficial.

Therefore, if you want to update the firmware, make sure to check the required hardware, and compare the performance differences between different mainboards to find the most suitable option.

3) Communication ports

The way of data transmission supported by the mainboard is quite important as well! This is not only related to the way you use it, but also restricts whether your printer can install a certain mainboard. Want to know why? Read on!

① correspondence

For most 3D printers, the main board is installed in the case at the bottom. Most of the time your only interaction with the mainboard is when you will plug the SD card/TF card/USB port into the slots reserved in the outer shell of the printer to transfer gcode or flash firmware. However, the experience of using a non-original mainboard will make you realize that it is not a matter of course that the ports of the mainboard exactly correspond to the slots on the printer shell. In more extreme cases, you may find your mainboard too large to sit in place. In this situation, if you still want to use this mainboard for the printer, you have the following options.

② What if it does not match the printer shell?

a. On the best occasion, if a Wi-Fi module is on the mainboard, you can transfer data via WIFI.

b. Before you fix the mainboard in the printer, drill a hole in the corresponding position of the printer shell to use the SD card/TF card/USB port.

c. Connect a Pi (like Raspberry Pi or MKS Pi) to the mainboard to use Klipper firmware so you don't need to plug in storage cards on the printer.

d. You can simply put the mainboard outside the printer. If you plan to do this, you must consider whether the power cable/thermal cable/motor cable, etc. are long enough.

e. Some display screens have slots for plugging cards, like MKS Mini 12864 V3.

The above methods may solve the problem, but you may wonder why the ports of the mainboard do not match the printer shell? In the development process of the mainboard, functions is prior to the adaptability of the ports to a specific printer. Only a few mainboards on the market will be specially developed for a certain printer, unless the printer has a large user base who are willing to upgrade and replace their mainboards (yep, the Ender series of Creality).

③ Recommendation

Therefore, Makerbase developed two mainboards, MKS Robin E3 and MKS Robin E3D, specifically for the Ender-3/Ender-5/CR-10 series and their clone models. The ports and sizes of the two mainboards are fully compatible with the case sizes of the Ender-3/Ender-5/CR-10 series, except that on some new printers, the original TF card ports have been replaced with SD cards(does not affect use). If you compare them with Creality V4.2.7, Creality's latest iconic mainboard, you can see the ports and reserved fixing screw holes are exactly the same configuration.

4) Upgrade features

In addition to the applicability, you will definitely consider what upgrade features the new mainboard can bring. If you just want to enjoy the plug-n-play new features, pay attention to checking the product description to confirm whether it supports the features you want.

① Auto-leveling:

In 2023, although auto leveling is now a standard feature of FDM printers, there are still many mainboards of old models that do not support auto leveling kit. In Makerbase.store, all the mainboards can support auto leveling kit.

② UART/SPI/I2C stepper driver communication:

Many MKS mainboards can execute different stepper driver communication types with jumper caps. The default communication only allows the stepper driver to receive data from the MCU, while UART allows the driver to send data back to MCU, so the MCU and each driver can communicate back and forth. It greatly enhances the data transmission between MCU and the driver and it can verify whether the data is received correctly. A more practical benefit is that the UART allows sensorless homing, which will save you a little money for the axis sensors.

SPI, on the other hand, sends data not only to a certain driver but also to all the other drivers at the same time. The advantage is that it can transmit data much faster and you can do it with less power.

I2C communication combines the good features of UART and SPI and is widely used as well.

③Filament-runout sensor:

This function allows your 3D printer to detect whether the filament spool is empty. Once triggered, your 3D printer will stop printing and wait for you to feed in another spool. Most importantly, it encourages you to use those spools with very little filament left.

④Compatible with more displays:

Some boards can only be used with a certain display, while others are compatible with multiple displays, saving you the cost of getting an additional display. Most of the MKS mainboards are compatible with multiple common display screens on the market, such as the most common 12864 knob screen and TS35, TFT35 touch screens, offering a wider compatibility of the existing 3D printer displays.

⑤Neopixel light strip:

Many players like to illuminate the print bed with Neopixel light strips, or make a cool lighting decoration on the 3D printer. Some mainboards have the ports for Neopixel, so your assembly can be convenient and direct, like MKS Robin E3 V1.1, MKS Robin E3D V1.1 and MKS Monster8 V2.